- +886-4-2350-8088

- Mon - Fri 8:00 - 17:00

Cultivate Talent

In-depth Talent Development and Nurturing

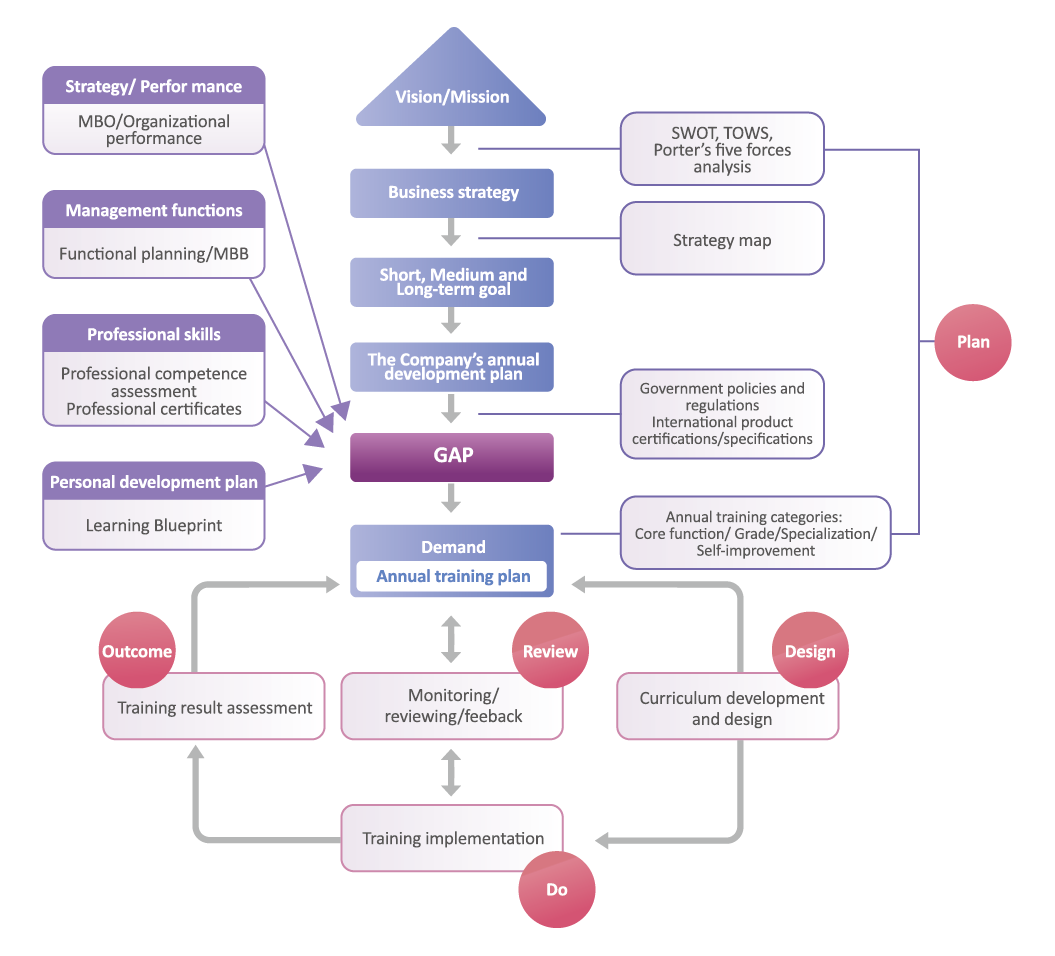

Here at YOKE, we emphasize holistic learning and development for employees. By taking the Company’s vision and mission into account and through the analyses of the internal/external operating environment (i.e. Porter’s five forces analysis, SWOT analysis, TOWS analysis and so forth), we were able to formulate our business strategies, from which we derive our short, medium and long-term development plans.

Our annual training plan is formulated each year in November based on the need for internal/external training submitted by different departments and YOKE’s annual development plan in conjunction with our internal On the Job (OJT) training to boost employees’ professional competence.

Digital Transformation of Learning and Development

Since 2020, Yoke has introduced a training platform to build diverse learning channels, progressively digitizing education and training course management to enhance learning convenience and meet employees’ autonomous learning needs, helping to improve overall work efficiency and innovation capabilities.

| Required Basic Courses | .In 2024, the Company continued to develop digital learning materials, with mandatory basic courses including product specifications, occupational safety, and manufacturing processes being 100% digitized. |

| Manufacturing Skills | .Since 2023, the Company has launched the “Manufacturing Skills Digital Course Project,” inventorying skills at each workstation and recording operational procedures. .In 2024, the Company continued to expand the recording of instructional videos and fully digitized its “skill certification courses,” requiring employees to complete online courses before participating in skill certification. .The skill certification approval process was also changed to online approval, optimizing review efficiency and reducing paper waste. |

| Research and Development & Engineering Expertise | .In 2024, the Company established 75 “Research and Development & Engineering Professional Knowledge and Skills E-Learning Courses,” covering everything from basic theory to advanced technology, supporting employees’ autonomous learning and strengthening their ability to solve technical problems. These courses can be combined with practical operations to enhance comprehensive skills, helping employees effectively apply their learned knowledge in their work. |

Training Roadmap

Training is implemented based on the operational strategies and talents deployment in correspondence to the organizational structure and vision. A comprehensive training roadmap is established based on the competence development needs. Courses are planned by job grade. Apart from planning required courses for professional training, quality control, and management, each year different training programs are offered in response to the future development strategies. By combining complete education and training plan with performance and development, we provide employees with opportunities for promotion and job rotation so as to develop all-round talents.

Achievement and Effectiveness Follow-up

The total training hours for all employees in 2024 was 12,409 hours, an increase of 4,027 hours compared to 2023, mainly due to increased annual professional courses and occupational safety training courses. The average training hours per employee was 23.55 hours, an increase of 5.9 hours compared to 2023. In 2024, more professional courses and corporate sharing sessions were conducted, with professional staff averaging an increase of 24.17 training hours and direct personnel averaging an increase of 3.47 training hours.

To confirm training effectiveness, the Company has referenced the “Kirkpatrick Model” to establish training evaluation indicators for each course, setting evaluation levels based on course planning and continuously using training course effectiveness assessments to confirm that trainees transform learned knowledge and skills into actions demonstrated at work. The 2024 training effectiveness is as follows:

- Average Course Satisfaction: 4.6 points

- Professional courses: A total of 339 courses including process, quality, environmental safety and health, and corporate knowledge sharing, with 100% of trainees completing post-course tests or reflection submissions.

- External certification courses: 104 people were arranged to participate in external professional certification courses related to environmental safety and health and quality, with 102 people passing, achieving a certification rate of 98%.

Level1

Reaction

Level2

Learning

Level3

Behavior

Level4

Result

Knowledge Management System

To accumulate internal key knowledge, pass on experience, and promote innovation, corporate knowledge review meetings are held monthly. Corporate knowledge that passes review is stored in the knowledge management center of the training platform, and cross-departmental exchange and learning are also promoted through physical sharing sessions and recorded online courses. The “Yoke Knowledge Management Platform” covers 12 types of knowledge maps including production, quality control, business management, human resources, finance, and labor safety, preserving key processes and knowledge from each department. Employees can engage in autonomous learning through the platform, accelerating learning and growth while enhancing professional knowledge.

The 2024 results are as follows:

- Corporate knowledge review: 10 items approved.

- Corporate Knowledge Sharing Sessions: 14 sessions were held, with 832 participants in physical sharing sessions and 93 participants in digital courses. Among these, in response to the introduction of a new process - the anodizing process - an “Introduction to Aluminum Alloy Anodizing” sharing session was conducted in 2024 to help employees in related departments understand the process flow and related equipment.

Skill Proficiency Test

To cultivate technical talent with diverse skills, a “Skills Assessment System” has been designed since 2017. Employees can obtain professional skill certification through systematic learning and passing evaluations. The assessment system is divided into three levels: A, B, and C, combined with the OJT system to provide education and training. Assessment items cover both written and practical examinations, and reassessment is required once a year to ensure continuous skill improvement.

To encourage employees to continuously enhance their professional capabilities, the assessment system is also coupled with an allowance system. Those who obtain intermediate and advanced level (Level B and C) skills assessments can receive corresponding allowances and skill badges to reward their professional achievements and improve manufacturing standards. Currently, the skills assessment system has been fully implemented in manufacturing, quality control, testing center, and materials management departments, promoting overall diversified skill development.

Level A

Level B

Level C

YOKE Industrial Corp.

#39, 33rd Road, Taichung Industrial Park, Taichung 407, Taiwan

E-mail: info@mail.yoke.com

Tel: +886-4-2350-8088

Quick Link

Other

Live In The Freedom

Follow Us: