Core Values and Takeaways from Outstanding Employees

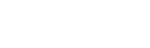

5A Core values

The 5A the core value of our code of conduct, and “accountability and integrity” comes the first. We request new employees to sign the “Integrity and Probity Commitment” on their arrival to promise compliance with the Code of Business Conduct and Ethics and not to engage in any improper conduct, such as illegal and unethical behavior, unfair competition, bribery, and corruption. Additionally, new employees must accept the orientation training that includes the 5A core value. In 2022, the rate of both signing the commitment and completing the orientation training was 100%.

Through the performance management system, we periodically assess the compliance and practice of the 5A core value of each employee to ensure that the corporate culture featuring “accountability and integrity, appropriate decisions, acquire customer loyalty, active learning, and aggressive innovation” in the daily work and decisions.

Accountability and integrity

Take accountability actively and make sure all decisions and behaviors are compliant with laws and the code of ethics.

Appropriate decisions

Make the best decisions for the corporation effectively and in a timely manner as w ell as put them into practice.

Acquire customer loyalty

Take customers’ needs as the top priority and endeavor to exceed customer expectations to create customer loyalty.

Active learning

Actively seek learning opportunities and effectively apply them to the job.

Aggressive innovation

Develop innovative and actionable solutions for the job and try to deal with problems at work or opportunities through different or new approaches.

Compliance

YOKE complies with domestic regulations in all its business operations. The Company also pays constant attention to policy trends, and reviews and revises internal policies or procedures where applicable to conform with the latest regulations. As a result, YOKE has been able to monitor and respond appropriately to changes in key policies and laws, whether local or abroad. YOKE had complied with pertinent laws and internal policies on economic, environmental and social aspects throughout 2022. There had been no violation concerning anti-corruption, finance, marketing communication, product information/labeling, labor laws or environment, and neither was the Company fined by competent authority for any violation.

With regards to product specifications, YOKE has an R&D Department that keeps a close eye on the world's standard developers and maintains good interaction with them to obtain news on the latest changes. As soon as new standards are issued, the Company conducts internal product reviews and makes design changes accordingly in order to deliver products with up-to-date specifications to customers.

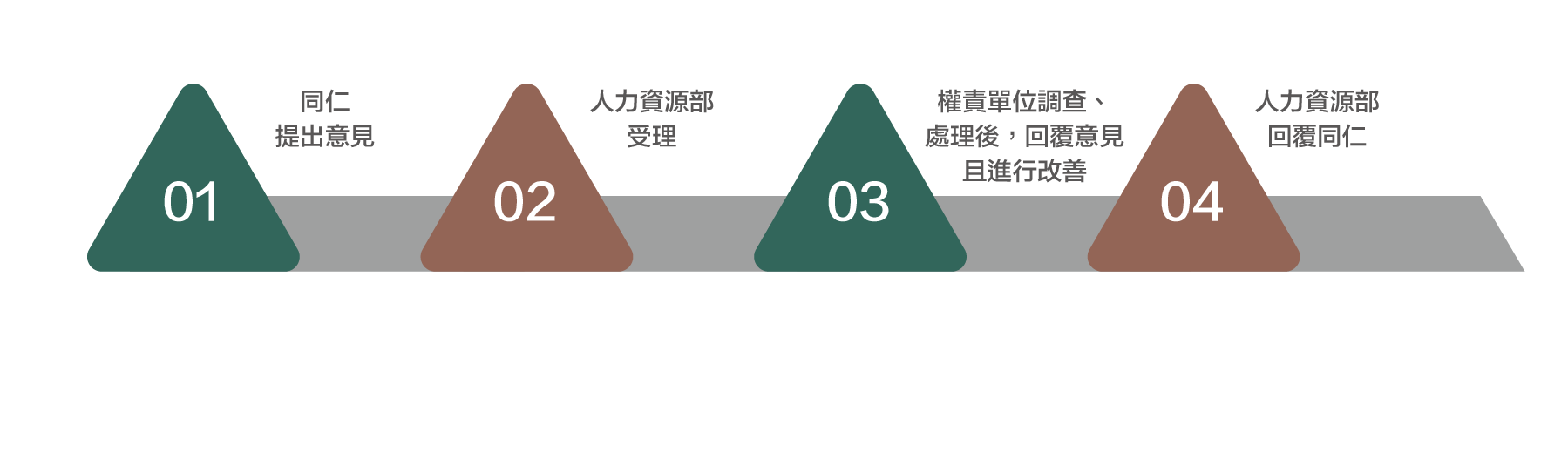

Grievance mechanism

YOKE has opinion boxes, e-mail, and sexual harassment complaint hotline available for employees to raise opinions or complaints. All opinions are collected and verified by the Human Resource Department before they are forwarded to relevant personnel of the responsible department. Replies are made collectively by the Human Resource Department. External parties can also lodge a complaint or provide their input via the “Contact us” section on YOKE’s website. In addition to classifying opinions by stakeholders' issues of concern (i.e. sales, procurement, human resource) and assigning dedicated personnel to collect and handle each category, feedbacks relating to internal misconducts such as corruption are directed to senior officers for confidentiality and more effective investigation/handling in the future. We had received zero complaints in 2022.