Improve product labeling

Product labeling

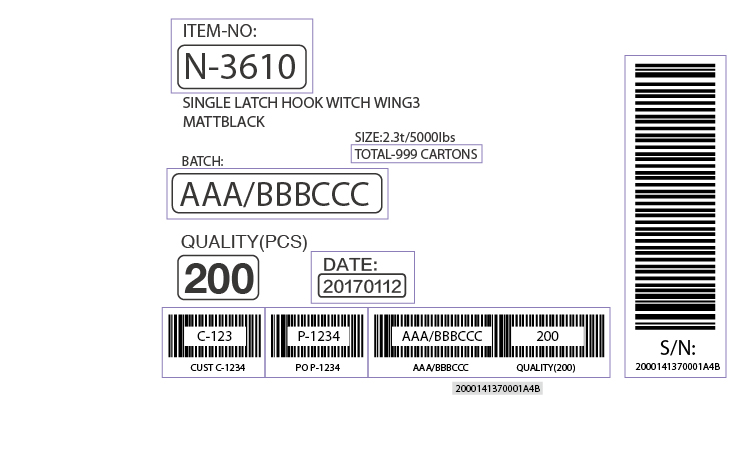

YOKE has adopted an automated warehouse storage system for precise control of inventorying and shipping operations. Through a barcode printing system, product information to be included in the packing box is printed out directly. The automatic warehousing system is designed to identify the boxes automatically by barcodes to expedite shipping and make it convenient for customers to extract information upon receipt of goods.

There are strict regulations governing product labeling for industrial safety lifting and safety protection. The name/trademark of manufacturer, the applicable regulation code, the manufacture lot number/year, and the force bearing direction/loading capacity, among other information (the required information to be shown differs slightly according to regulations for different product lines) must be labeled. During the development of products, YOKE already completes proper designs and inspections regarding the appearance treatment process flow for die/laser engraving to ensure that products are labeled in compliance with applicable regulations.

Product lineup digital-assisted product labeling and document provision

To solve the long-time hidden safety problems in the industrial lifting industry, such as product labeling failure, missing paper safety operation instructions, personnel’s failure in long-term implementation of equipment safety check before use, we started the product lineup digitization project in 2017. By embedding the RFID chip in products and through the support of cloud software, we store manufacturer production records (traceability), safety operation instructions, and equipment safety check records on the cloud and systemically manage component use time, inspection schedules, and inspection methods with digital tools to enhance industry safety.

With the app from our partner RiConnect, customers can quickly access manufacturer information, RFID’s unique code and serial number, product traceability information, manufacturer compliance certificate, product operation instructions, and product inspection records before use over the smartphone or easy reader to enhance the convenience and safety of product use and achieve paperless operation for environmental protection.