Ongoing improvement of production procedures

e-Production management of Factory 2

To optimize production management, we introduced the MES system in Factory 2. Through the IoT, we bound the information of the relevant machines with orders to trace the lot number of abnormal materials and display the information on the digital signage so as to keep production lines updated with the actual condition. Apart from saving labor and time for manual reporting, e-reporting can reduce the risk of report errors. Through e-management, data generation in process monitoring is smoother to enhance production efficiency.

Process Improvements

YOKE uses the total quality management system to continuously carry out quality improvement activities, promotes CIT improvement activities, and establishes the cultivation guidance system and the operation system of continuous improvement. By cultivating internal seed employees, the quality improvement practices are deepened within the company and implemented as part of the company's daily operations; systematic tools are introduced to make quality improvement activities more efficient and effective, and finally, innovation and improvement, team learning, and continuous learning become part of the corporate culture of YOKE to continuously improve and innovate, and also enhance customer satisfaction.

| Improvement examples | Boost efficiency | Increase output | Optimize human resource | Reduce material consumption |

|---|---|---|---|---|

| Introduction of the forging i-forming system | v | v | ||

| Automatic spray of release agent in forging | v | v | ||

| Dryer timer improvement (including date setting now) | v | |||

| Steel cable winding tool | v | v | ||

| Automated stamping machine spring | v | |||

| Improvement of YKN94* series steel cable drawing | v | v | ||

| Processing process automated measurement project | v | |||

| Production line dispenser improvement | v | |||

| Introduction of the N-3615 automatic riveting machine | v | v |

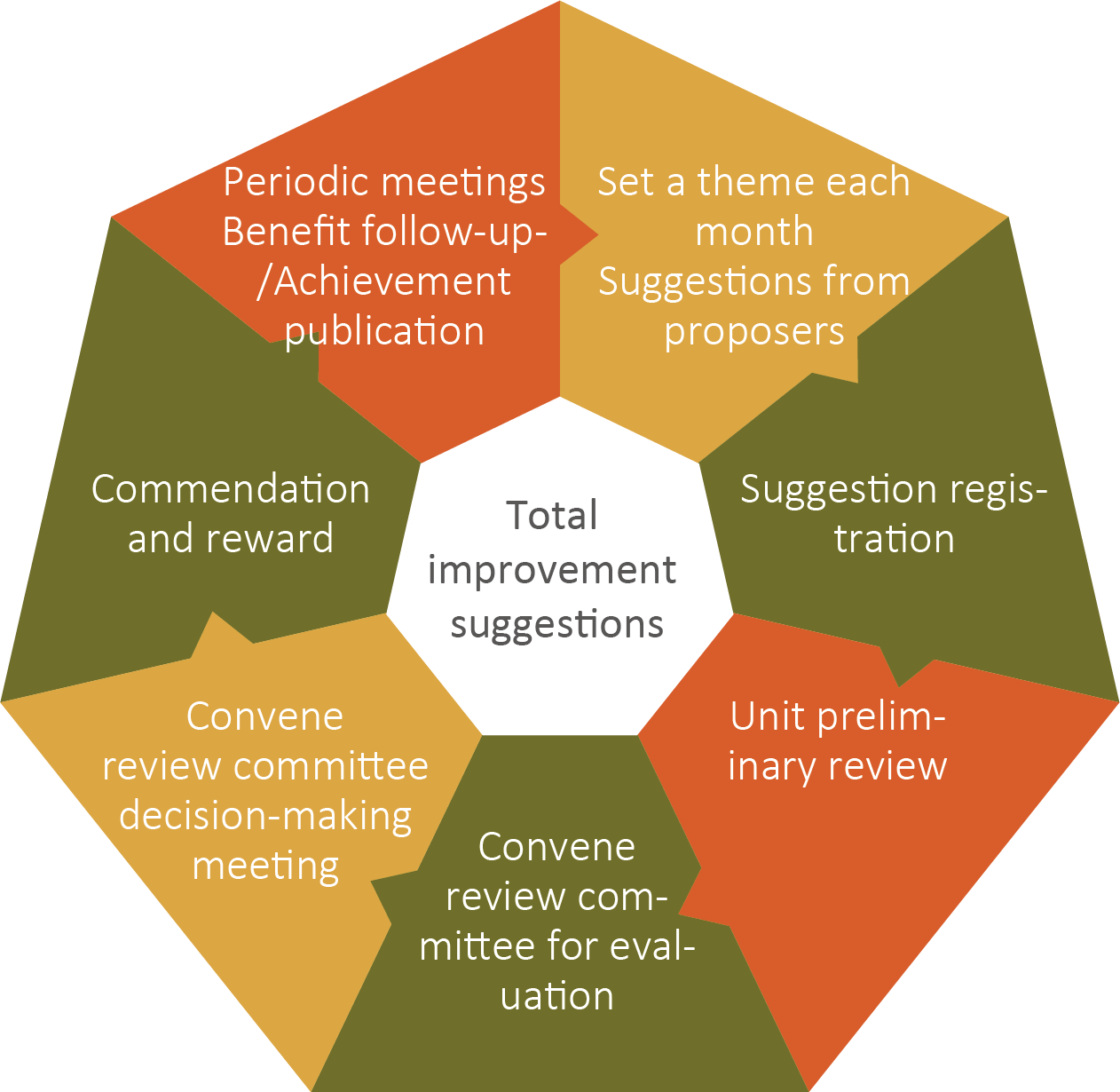

Total improvement suggestions

We introduced the total improvement suggestion system in July 2021 to encourage direct labor to make one improvement suggestion each month. The unit head will conduct the preliminary review, and each unit select at least once highlight suggestion. Through the review of the assessment team, three excellent highlight suggestions were selected each month, and employees making the suggestion were commended at the morning assembly.

In 2022 director labor made 2,446 improvement suggestions in eight “objectives of improvement suggestions”. A total of 90 suggestions were reviewed for PDCA by the review committee to create benefits for up to NT$1.93 million. The monthly average of suggestions per employee was 1.07 suggestions. Apart from commending the proposers of the three highlight suggestions each month, we also rewarded the Idea King Bonus to the employee making the most suggestions each month.

Reward individuals with outstanding performance in improvement suggestions for using various improvement tools to make specific improvements. This not only brings honors to individuals but also enables employees to develop the capability to find problems and make suggestions for improvement and so to make continual improvement part of our corporate culture to accumulate knowledge and capability to develop corporate sustainability.

Total productive maintenance (TPM)

Building upon the foundation of promoting 6S that began in 2015, YOKE has examined various areas for improvement in the work environment from the aspects of man, machine, material, method, environment and safety and has gradually improved various standard operating procedures. With the groundwork set, we launched our Total Productive Management in 2019 in order to further enhance the efficiency and outcome of our manufacturing processes so that we can establish a solid foundation to bolster the Company’s sales performance. Initially, we focused on the establishment of independent maintenance subcommittees and individual improvement subcommittees. Committees dealing with improvement issues at moderate or low difficulty have been classified as independent maintenance subcommittees, with the corresponding departments taking charge of the improvements. Promoting planned maintenance KPIs was our focus in 2022. Through the project, we found 173 items with room for improvement on grade A important equipment, and the performance was outstanding . When implementing TPM, we can also achieve energy conservation by enhancing machine utilization rate and energy efficiency or reducing energy consumption through schedule adjustment, stock control, and personnel training

| Planned Maintenance KPI Promotion | |

|---|---|

| Shorten mean time to recovery (MTTR) of important equipment | The 2022 monthly MTTR reduced by 4.6 hours (50%) over 9.6 hours in 2021 to 4.6 hours. |

| Extend mean time between failures (MTBF) of important equipment | The 2022 MTBF was extended by 607 hours (38.08%) over 1,594 hours in 2021 to 2,2021 hours. |

| Reduce repair expenses | Completed 21 individual improvement projects to save costs by NT$752,300. |

Management innovation: Equipment “e-check” pilot project

In have been promoting “product digitization” in recent years. After launching the SupraTag, we began implementing internal equipment management in 2021. By combining with RFID devices and digital platforms, we performed daily/weekly/monthly checks, maintained machine maintenance records, and reported anomalies. With big data management, we conducted preventive maintenance and implemented management policies. By the end of 2022, we already implemented total digital check for up to 172 machines. In the future, we will implement digital management on all production-related important equipment and include digital mechanisms in all new equipment, which is part of the criteria for inspection and acceptance. In the future, we hope to extend our implementation experience to equipment suppliers and establish equipment check/maintenance document templates for other suppliers to download and use so as to continuously promote the application of digital check.